Cosmetic Quality Control

Our Commitment to Product Safety and Performance

At Safeguard SCI, quality is not an afterthought—it’s built into every stage of production. From raw material sourcing to final product release, our quality control system ensures that every product is safe, stable, and effective.

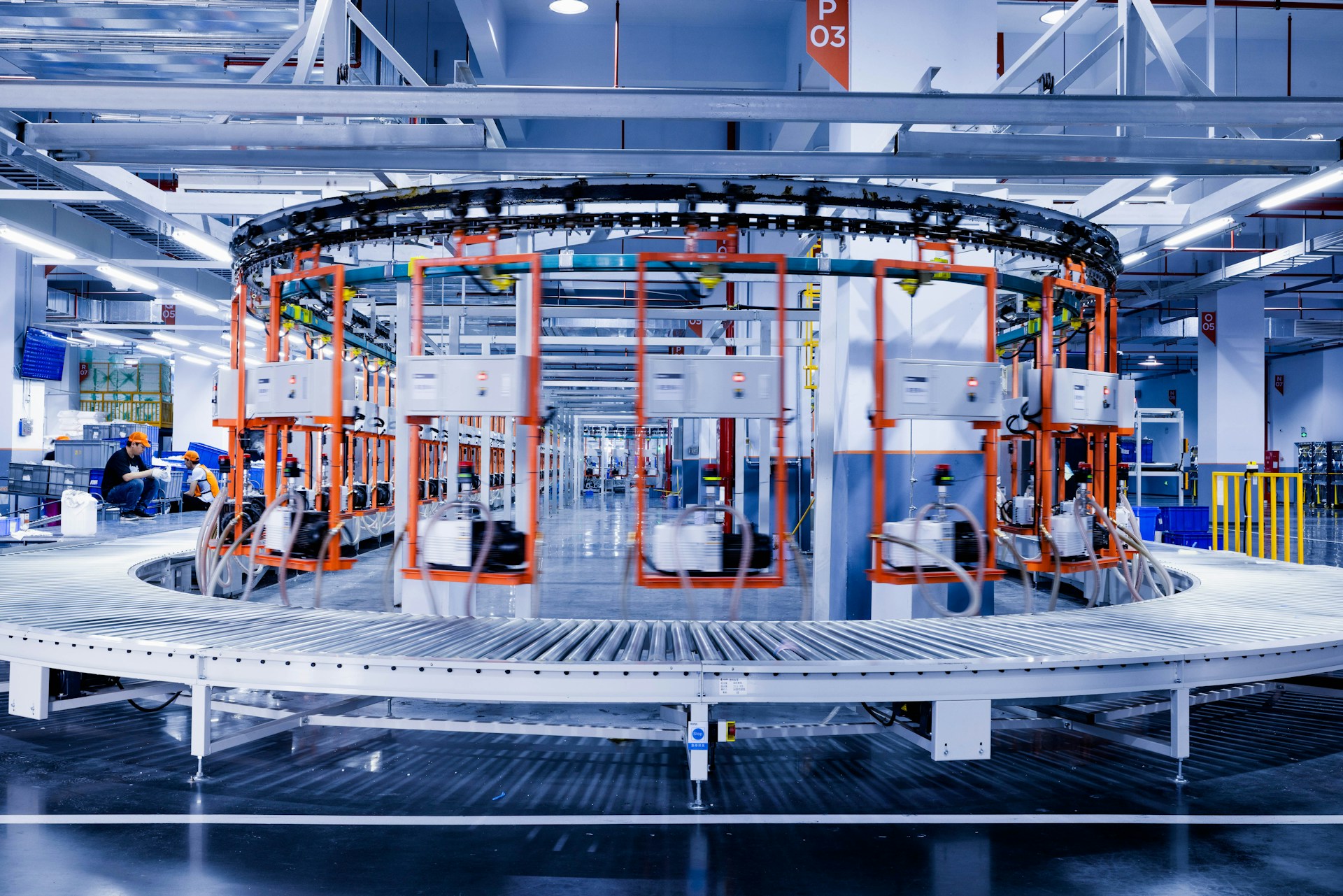

Full-Process Quality Control

We maintain strict quality oversight across all areas—raw materials, packaging, production, storage, and the working environment. Each product is evaluated for both its functional performance and its physical and chemical stability

Step-by-Step Quality Control Process

Raw Materials

Every ingredient undergoes specification testing to confirm it meets required standards before being approved for use.

Packaging Materials

Before procurement, we conduct compatibility testing. Each packaging unit is inspected for capacity, appearance, leak resistance, and durability. Only approved items are cleaned, sterilized, and cleared for use.

Semi-Finished Products

In-process formulas are evaluated through physical and chemical tests, including: Sensory analysis, pH testing, Heat/cold resistance and Microbiological analysis

Filling & Packaging

We verify the weight, volume, formulation, and packaging materials before the filling process begins, ensuring alignment with product specifications.

Finished Goods

Final products undergo microbiological and physico-chemical testing to confirm stability and safety. A Certificate of Analysis (COA) and Material Safety Data Sheet (MSDS) are provided upon delivery.

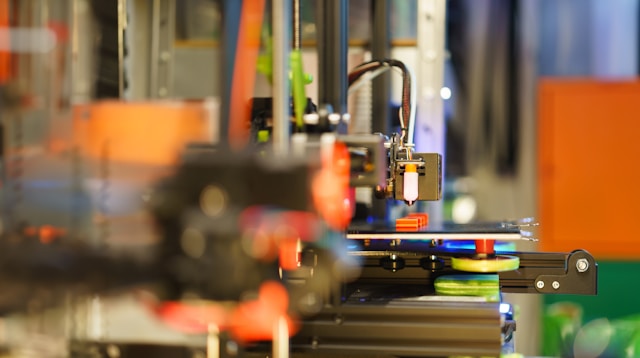

Cosmetic Testing Methods

Our quality assurance extends beyond development and production—we continue testing through to final shipment to guarantee performance and consistency.

Our testing protocols include:

⇔ Specific Gravity (SG)

⇔ Smell & Sensory Evaluation

⇔ pH Balance

⇔ Viscosity

⇔ Aesthetic/Appearance Review

⇔ Microbial Contamination

⇔ Long-Term Stability

⇔ Selective Heavy Metal Testing

We also employ barcode tracking and digital inventory systems to monitor raw material flow and reduce the risk of manual error—enhancing both quality and efficiency.